Understanding the Relevance of Stretch Wrapper Repair Service for Optimum Product Packaging Performance

Stretch wrappers play a necessary duty in ensuring packaging efficiency across various industries. Their performance can be jeopardized by typical issues that arise over time. Neglecting repair work can result in significant functional setbacks and monetary repercussions. Comprehending the indicators that show maintenance is required is important for maintaining productivity. This brings up the questions of exactly how firms can effectively manage their stretch wrapper upkeep to maintain and protect against interruptions high quality.

The Duty of Stretch Wrappers in Product Packaging Effectiveness

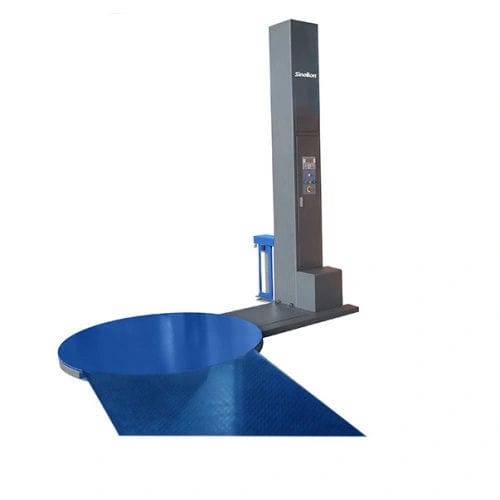

Stretch wrappers function as vital components in the packaging process, significantly boosting effectiveness in various industries. These makers make use of stretch film to safeguard products on pallets, lessening activity throughout transportation and storage space. By firmly wrapping products, stretch wrappers shield them from contamination, damages, and dampness, ensuring they reach their location intact.In addition to guarding products, these wrappers simplify the packaging process. Automated stretch wrapping systems considerably raise output, lowering time and labor costs connected with hands-on product packaging. The consistent application of stress in the covering process also maximizes material use, leading to cost financial savings and decreased waste.Moreover, stretch wrappers can be gotten used to accommodate various item shapes and sizes, providing versatility in product packaging procedures. This versatility enables companies to enhance their general productivity, maintain high standards of quality control, and enhance consumer complete satisfaction via dependable shipment of well-packaged products.

Usual Issues That Affect Stretch Wrapper Performance

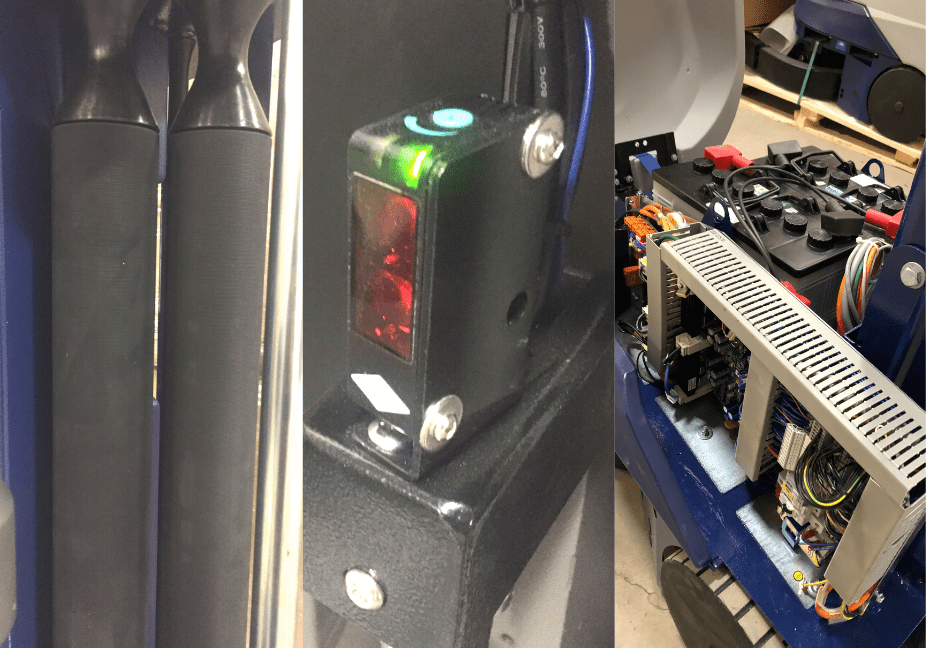

Packaging performance can be substantially prevented by different issues that impact stretch wrapper efficiency. One typical problem is irregular stress during the wrapping procedure, which can cause insufficient tons stability (stretch wrapper repair). Furthermore, malfunctioning sensing units may fail to find the tons elevation, leading to incorrect covering and lost materials. Deterioration on elements such as belts and rollers can likewise interrupt the smooth operation of the device, causing hold-ups and possible damages to products. Another issue is the high quality of the stretch film itself; substandard materials can tear conveniently or fall short to adhere appropriately to the tons. Routine maintenance is essential to recognize and fix these problems before they escalate. Inevitably, making certain peak efficiency of stretch wrappers not only improves product packaging effectiveness but additionally protects product honesty throughout the supply chain. Addressing these common concerns is essential for keeping efficient product packaging procedures

The Financial Influence of Overlooking Stretch Wrapper Fixes

Neglecting stretch wrapper fixings can result in significant financial consequences for organizations. Increased packaging costs and long term downtime cause productivity loss, ultimately affecting the bottom line. Dealing with these repair work quickly is necessary to maintain operational performance and cost-effectiveness.

Boosted Product Packaging Costs

In time, falling short to resolve required repairs on stretch wrappers can lead to substantial financial repercussions for businesses. As equipment breakdowns or wears down, packaging performance diminishes, leading to raised material usage. This can show up as the need for more stretch movie to safeguard lots effectively, raising general product packaging prices. In addition, badly covered products may bring about harm during transit, necessitating extra expenditures for replacements and customer compensation. Business may likewise locate themselves purchasing expedited delivery to change harmed items quickly, which additionally stresses their budget plans. Inevitably, disregarding stretch wrapper repairs not only boosts immediate product packaging prices yet can additionally add to long-term financial instability, influencing earnings and competition on the market.

Downtime and Performance Loss

Downtime positions a substantial risk to functional effectiveness in any kind of service relying upon stretch wrappers. When these makers experience malfunctions, manufacturing halts, resulting in considerable productivity losses. Each hour of inactivity not just undermines process but likewise increases labor expenses as staff members remain idle. In addition, delayed shipments can damage consumer partnerships and tarnish a business's track record. The monetary effects are extensive; neglecting prompt repair services can bring about collective losses that far exceed the price of maintenance. By focusing on stretch wrapper upkeep, organizations can lessen downtime, boost performance, and guarantee consistent functional flow. Ultimately, buying normal repair services safeguards success and sustains affordable advantage in a demanding market.

Indications That Your Stretch Wrapper Requirements Upkeep

Exactly how can one tell when a stretch wrapper needs maintenance? A number of indications indicate that a stretch wrapper might not be running at peak efficiency. First, irregular covering tension may cause excessively tight or loosened loads, jeopardizing bundle stability. Furthermore, if the machine creates excessive sound or vibrations throughout procedure, it might symbolize worn elements that need interest. Operators must additionally observe the movie's application; if there are creases or tears, this might indicate concerns with the film carriage or the tension settings.Frequent error messages or alarms throughout operation are one more clear indication of possible issues. If the cycle time rises, it might recommend that the stretch wrapper is struggling to carry out at its ideal. Regularly checking for these signs can help guarantee that maintenance is scheduled prior to even more significant concerns occur, ultimately adding to the general efficiency of the packaging procedure.

Benefits of Normal Stretch Wrapper Maintenance

Normal maintenance of stretch wrappers supplies considerable advantages for packaging operations. It not only expands the life-span of the tools but likewise lessens downtime costs and boosts the overall quality of packaging. By focusing on maintenance, business can improve performance and guarantee constant efficiency in their packaging processes.

Raised Equipment Life Expectancy

Preserving a stretch wrapper not just boosts product packaging efficiency but also substantially expands the tools's lifespan. Regular maintenance techniques, such as cleaning, lubrication, and timely replacement of used components, stop premature damage, guaranteeing that the machine operates at peak efficiency. By attending to minor problems prior to they intensify, drivers can stay clear of significant damages that could bring about costly repair work or the demand for a total replacement. Furthermore, consistent upkeep fosters a much better understanding of the equipment's operational limitations, enabling suitable usage without overexertion. This positive method ultimately adds to a much longer operational life for the stretch wrapper, making best use of the return on financial investment for services and making sure reliability in their packaging processes.

Minimized Downtime Expenses

Efficient procedures hinge on minimizing downtime, especially in high-demand packaging settings. Routine upkeep of stretch wrappers significantly lowers the chance of unforeseen breakdowns, which can bring about expensive production halts. By proactively dealing with small problems prior go to this site to they intensify right into major failings, business can assure that their product packaging lines stay operational. This preventive strategy not only conserves time however likewise reduces labor prices connected with emergency situation repair services and unplanned downtime. In addition, consistent maintenance enables better organizing of repairs, leading to less disturbance during optimal functional hours. As a result, the total performance of the packaging process improves, equating into higher effectiveness and cost savings for the organization. Normal stretch wrapper maintenance is crucial for preserving operational consistency in open markets.

Enhanced Packaging High Quality

When stretch wrappers are effectively preserved, the quality of product packaging can significantly boost, guaranteeing that items are firmly wrapped and protected during transportation and storage. Regular upkeep helps in recognizing and remedying potential issues before they intensify, such as imbalance or endure parts, which can compromise the wrapping process. This proactive method not only enhances the honesty of the covered products however additionally minimizes the threat of damages triggered by environmental aspects. Furthermore, regularly well-maintained stretch wrappers add to uniformity in packaging, making certain that each lots fulfills the needed criteria. Eventually, improved packaging quality leads to enhanced client contentment, minimized return rates, and a stronger credibility for reliability, all of which are essential for sustained business success.

Selecting the Right Fixing Solution for Your Stretch Wrapper

Selecting the suitable fixing solution for a stretch wrapper is vital to maintaining packaging effectiveness and lessening downtime. Organizations ought to prioritize solutions that concentrate on stretch wrapper fixings, as these suppliers have the required proficiency and experience. Evaluating the service technician's certifications and the solution provider's reputation can considerably influence fixing quality.Additionally, it is useful to think about the availability of substitute components and the speed of service. A reputable repair work solution should not only supply prompt assistance however also provide guarantee alternatives for their work, guaranteeing long-term confidence in repairs.Furthermore, companies must seek out endorsements and testimonials from other customers to determine the solution's performance and integrity. Transparent interaction pertaining to expenses and repair work timelines is additionally crucial in establishing count on. Ultimately, picking the best repair work solution can bring about enhanced functional performance, reduced expenses, and boosted efficiency for businesses counting on stretch wrappers for their packaging requires.

Best Practices for Stretch Wrapper Maintenance and Longevity

Regular maintenance is vital for guaranteeing the long life and ideal performance of stretch wrappers. Constant assessments should be conducted to recognize wear and tear on parts, such as belts, rollers, and motors. Oiling relocating components at suggested periods minimizes friction and extends equipment life.Furthermore, drivers must be educated to make use of the machinery appropriately, as improper handling can bring about premature failings. Maintaining the work area totally free and tidy of debris minimizes the threat of mechanical damage and advertises a safe working environment.Replacing used or broken parts promptly is essential; this prevents minor issues from rising into expensive repairs. In addition, preserving a log of upkeep activities aids track the performance and solution background of the stretch wrapper.

Frequently Asked Questions

How Commonly Should Stretch Wrappers Be Serviced for Optimum Performance?

The frequency of servicing stretch wrappers typically relies on usage intensity. Typically, makers suggest evaluations every 6 to year, ensuring peak performance and decreasing unexpected downtime through proactive upkeep and timely fixings.

Can I Do Repairs on Stretch Wrappers Myself?

The private contemplated whether they can do repair work on stretch wrappers themselves. stretch wrapper repair. It was kept in mind that while some minor modifications could be workable, expert proficiency is often suggested for intricate issues to assure safety and security and capability

What Components of a Stretch Wrapper Are A Lot Of Prone to Failure?

Stretch wrappers typically experience failures in components such as the movie carriage, drive motors, and sensors. These parts are important to the equipment's procedure and may require normal upkeep or timely replacement to assure peak efficiency.

How Does Environmental Impact Impact Stretch Wrapper Performance?

Ecological elements, such as humidity and temperature level changes, can considerably influence stretch wrapper performance. These problems may result in material degradation, irregular wrapping stress, and inevitably, reduced effectiveness in the product packaging process. Regular analyses are crucial.

Exist Particular Brands Recognized for Better Durability in Stretch Wrappers?